Our Definition of Pickling

What does Pickling mean to us? No, we donít pickle cucumbers and we're not spending time getting pickled at the bar.

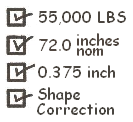

Granite City Pickling is a toll-processor of carbon steel, flat rolled coils. Many of these pickled coils will end up in automotive, agricultural and construction markets. These coils can weigh an average 40,000 pounds, up to 72" in width and up to 3/8" in thickness. The method of pickling is to remove scale and oxides from the surface of the strip, with a solution of hot hydrochloric acid. When steel coils are created at a integrated steel mill or a mini mill, a layer or crust or scale is formed from the cooling and rolling processes. The scale is mainly made up of carbon and traces of manganese and silicon and is therefore hard and abrasive. This scale needs to be removed for most downstream operations such as making cold rolled and galvanized steel, and press or forming applications.

The coiled steel strip is unwound with on an uncoiler in a manner much the same as pulling a paper towel from the spool. This is the peeler section and it delivers the strip into the flattener where any coil set is removed . Coil set is the memory induced into the strip from the mill, in much the same manner a paper towel section will exhibit this same trait if laid down on a flat surface.

Now the steel strip is fed through a cleaning and preheating section. This stage removes any loose scale and contaminants before the metal enters the acid section. Pre-heating the strip allows the next step, the pickling process, to work faster and increase the speed the strip is traveling through the tanks.

At this point, the strip enters a shallow bath of hot hydrochloric acid in tanks made of specialized granite . Granite is naturally acid resistant. The acid dissolves the scale and leaves the strip clean, smooth and imparts a shiny surface.

After the pickling process, the strip needs to be rinsed off. This is done in a multistage rinsing system with hot water, that is recaptured, neutralized and reused again.

Once the material is clean, rinsed and dried, a thin coating of protective oil is applied. This keeps the surface from oxidizing (rusting) until it reaches the next processor or end-user. The steel strip is wrapped up on a recoiler, in much the same manner as it was uncoiled.

From here the freshly pickled coils are shipped off to be further processed into stamped and formed parts, cut into sheets or many other uses.

For an even more complete definition of Pickling here is Wikipedia's version.

To Provide 100% customer satisfaction

To ensure our end-product meets or

exceeds the customer's requirements